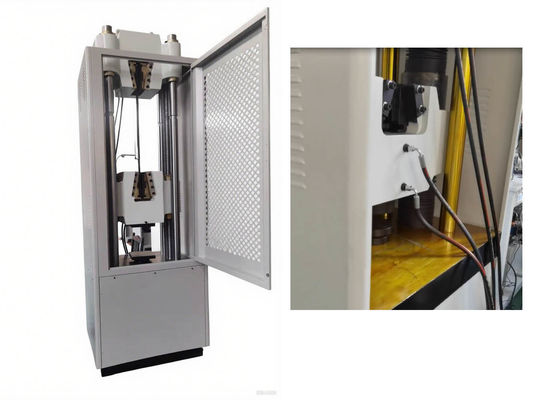

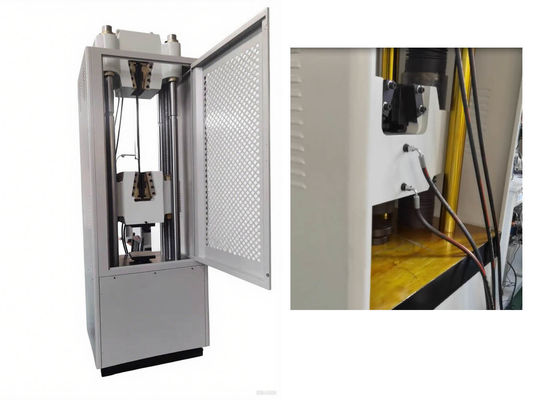

Mesin pengujian servo hidrolik dengan operasi pengujian yang dikendalikan komputer dan tampilan data waktu nyata untuk analisis material yang akurat

Aplikasi

Servo Hydraulic Testing Machine ISO-compliant untuk Stranded Steel Wire Tensile Testing memiliki aplikasi yang luas, mendukung tarik, kompresi, lentur, geser, mengelupas,dan pengujian sifat mekanik lainnya pada logam, non-logam, dan bahan komposit.

Baik operasi uji dan pemrosesan data sepenuhnya sesuai dengan GB / T 228-2010 Bahan logam - pengujian tarik pada suhu sekitar - memastikan hasil uji akurat, dapat diandalkan,dan sesuai dengan standar teknis nasional.

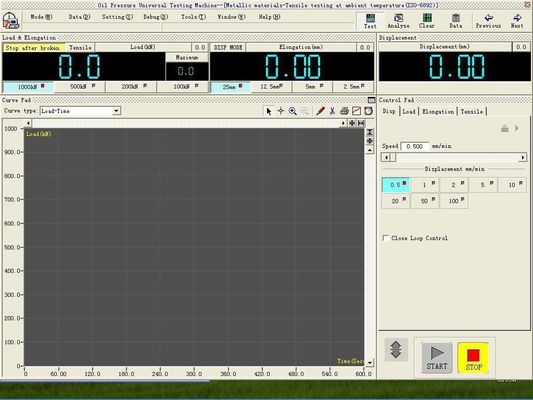

Seluruh proses pengujian sepenuhnya otomatis melalui kontrol komputer, menampilkan visualisasi data pengujian real-time, generasi otomatis dari beberapa kurva pengujian (misalnya,kurva tegangan-tekanan) dan laporan uji yang komprehensif, serta penyimpanan data yang aman dan fungsionalitas cetak sesuai permintaan.

Peralatan pengujian berkinerja tinggi ini banyak digunakan di sektor utama termasuk metalurgi, konstruksi, industri ringan, penerbangan, kedirgantaraan, ilmu material, universitas,dan lembaga penelitian ilmiah - berfungsi sebagai alat inti untuk kualifikasi materi, kontrol kualitas produk, dan inovasi R&D.

Keuntungan Harga

Kami telah secara signifikan mengintensifkan inisiatif R&D internal, mendirikan pusat pemesinan khusus, dan secara independen memproduksi komponen inti.Integrasi vertikal ini memungkinkan optimasi biaya di seluruh rantai pasokan tanpa mengorbankan kualitas produk.

Peralatan pengujian berkualitas tinggi kami memberikan penghematan biaya jangka panjang yang lebih besar dibandingkan dengan alternatif yang murah dan berkualitas rendah.Kami tidak hanya mengurangi biaya pemeliharaan klien kami tetapi juga meningkatkan efisiensi operasional - memastikan alur kerja pengujian tanpa gangguan.

Rasio kualitas dan biaya yang optimal ini memberikan nilai nyata dan berkelanjutan bagi klien kami, menyeimbangkan kinerja yang dapat diandalkan dengan manfaat ekonomi.

Standar Kepatuhan

ISO 6892, ISO 6934 BS4449, ASTM C39, ISO75001, ASTM A370, ASTM E4, ASTM E8 dan standar BSEN.

ASTMA370, ASTME4, ASTME8, ASTME9, ASTMA615, ISO6892, ISO7438, ISO7500-1, ISO 15630 ISO 6934, EN10002-4, GB/T228-2002, GB 16491-2008, HGT3844-2008 QBT 11130-1991, GB13-22-1991, HGT 3849- 2008,GB6349-1986, GB/T 1040.2-2006, ASTM C165, EN826, EN1606, EN1607, EN12430 dll.

Fitur Host

Microcomputer-Controlled Electro-Hydraulic Servo Universal Testing Machine mengintegrasikan kontrol otomatis, pengukuran presisi, akuisisi data, tampilan real-time di layar,dan analisis hasil tes dalam satu sistem terintegrasiIni mengadopsi mesin utama di bawah silinder sebagai platform inti,Dilengkapi dengan pompa minyak presisi tinggi dan pengontrol servo berbasis PC -- memungkinkan kontrol loop tertutup multi-saluran untuk sepenuhnya mengotomatisasi proses pengujian, termasuk fungsi kontrol otomatis dan pengukuran presisi.

Fitur utama produk termasuk profesionalisme teknis yang kuat, keandalan operasional yang tinggi, dan mudah ditingkatkan.Fungsionalitasnya dapat terus diperkaya dan dioptimalkan sesuai dengan kemajuan teknologi pengukuran dan kontrol mesin pengujian dan pembaruan standar pengujian internasional / nasional, memastikan kompatibilitas jangka panjang dengan kebutuhan industri yang berkembang.

Parameter teknis utama

| Model |

WAW-300D |

| Max. kekuatan uji ((kN) |

300KN |

| Struktur |

Empat kolom dua sekrup bola, jenis set-down tabung minyak |

| Jangkauan beban |

1%-100% |

| Kecepatan pengangkat balok tengah (mm/menit) |

250 mm/menit |

| Max. Ruang tarik (mm) |

700 mm |

| Ruang kompresi maksimum (mm) |

600 mm |

| Jalur piston ((mm) |

200 mm |

| Rentang penjepit kawat bergaris |

Φ4-32mm |

| Kekuatan total |

2.2KW |

| Ukuran pelat kompresi |

Φ160mm |

| Jarak rol dukungan lentur |

300 mm |

Pertanyaan yang Sering Diajukan

Q1: Apakah perusahaan Anda adalah perusahaan perdagangan atau fasilitas manufaktur?

A1: Kami beroperasi sebagai Integrated Manufacturing & Trading Enterprise - dengan 18 tahun fokus khusus pada sektor instrumen pengujian dan 14 tahun pengalaman ekspor.Model terintegrasi vertikal kami menggabungkan kemampuan produksi internal dengan layanan perdagangan global untuk memberikan biaya yang efektif, solusi berkualitas tinggi.

Q2: Bagaimana saya bisa memilih produk yang paling cocok untuk kebutuhan saya?

A2: Tim teknis profesional kami akan memberikan rekomendasi yang disesuaikan setelah Anda berbagi persyaratan pengujian spesifik Anda, termasuk jenis pengujian, standar yang berlaku, spesifikasi sampel,dan parameter kinerjaKami memanfaatkan keahlian industri untuk mencocokkan Anda dengan solusi peralatan yang optimal.

Q3: Apa syarat pengiriman Anda?

A3: Dalam kebanyakan kasus, kami menyimpan stok siap dari model standar di pabrik kami untuk pengiriman segera.Waktu pengiriman standar adalah 15-20 hari kerja setelah menerima pembayaran mukaJika Anda memiliki kebutuhan mendesak, kami dapat mengatur produksi prioritas untuk mempersingkat siklus pengiriman - tolong beri tahu kami jadwal Anda untuk koordinasi khusus.

Q4: Apakah Anda menawarkan layanan kustomisasi?

A4: Ya, kami menyediakan layanan kustomisasi yang komprehensif. Selain rangkaian produk standar kami, kami dapat mengembangkan instrumen pengujian yang disesuaikan berdasarkan persyaratan teknis unik Anda,skenario aplikasiKami mendorong Anda untuk berbagi spesifikasi rinci, dan R & D dan tim rekayasa kami akan berusaha untuk memenuhi permintaan kustomisasi Anda.

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!